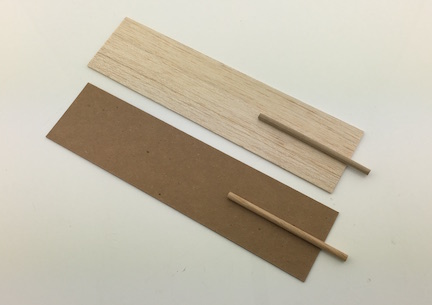

The best way to attach either chipboard or balsa wood to a dowel so it can be used with a KidWind Wind Turbine Hub is to use glue.

If time is short, the best quick-curing option we have found is regular hot melt glue, applied with a standard glue gun. Thin and fat glue sticks work equally well.

If time is available, standard white glue (also known as PVA glue) such as Elmer’s works well and generally weighs less than hot melt glue because less glue is used. Dowels will have to sit on blade materials without moving long enough for the glue to cure.

Tape does not work well, as it does not secure the blade material to the dowel tightly enough to prevent blade wiggle. Blades constructed with tape may not maintain a constant blade angle and tend to loosen over time.

Glue dowels to blade materials with less than 1 inch (2.45 cm) of dowel beyond the end of the blade. This allows the blade to catch more wind close to the hub than when more than an inch of dowel is exposed. While it is standard to glue dowels to the center of the blade material, students may decide that they want to investigate any difference in power production when the dowels are glued closer to the leading or trailing edge of the blade material.