Go Direct Wide Range Pressure

Liquid & Gas Compatible: GDX-WRPL

⚬ Specifications and User Guide

Gas Compatible Only: GDX-WRP

⚬ Specifications and User Guide

Troubleshooting

General: Press the power button on the sensor to turn it on. Connect your sensor as described in the Getting Started instructions for your device.

- Primary Test: Connect the sensor to a Vernier interface and run the data-collection program. The units for the default readings are kPa and they should be reasonable for the altitude at which the sensor is being used (around 101 kPa at sea-level). If you plug the output with your finger, the pressure should rise slightly (~5 kPa).

To ensure an airtight seal, use the included plumber’s tape on the pressure sensor’s threading.

Wrap only once and to the right, as the threading runs.

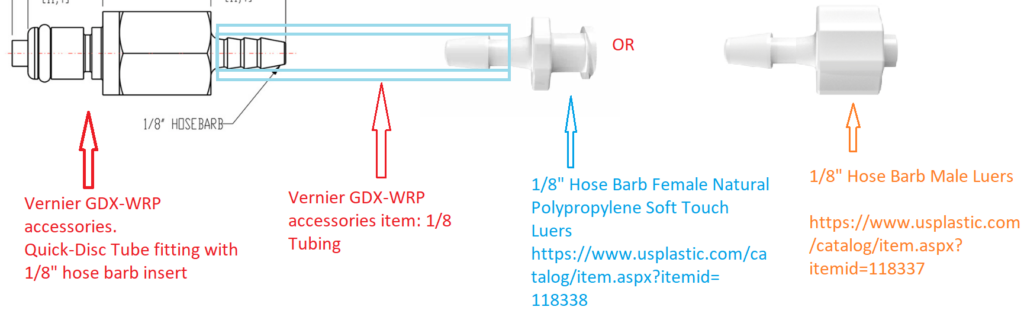

Alternative Connectors

Go Direct Wide-Range Pressure comes with two quick disconnect fittings as noted below. Also included is a two-foot section of plastic tubing designed to fit over the hose barb connector. Its standard size allows you to connect to a variety of third-party instrumentation or adapters.

- Chrome-plated Brass Quick Disconnect Tube Fitting with 1/8” NPT thread insert

- Chrome-plated Brass Quick Disconnect Tube Fitting with 1/8” hose barb insert

If you wish to purchase different quick disconnect inserts or replacements, many are available and compatible with the sensor. Contact chemistry@vernier.com for recommendations.

Unfortunately, there is not a quick disconnect luer lock option at this time. Below is an option for a luer lock set up:

Compatible Liquids—GDX-WRPL only

The GDX-WRPL features a Parylene C coating, renowned for its excellent chemical resistance and barrier properties. This coating provides protection against a variety of chemicals, making the sensor suitable for numerous laboratory applications. However, it’s essential to understand its compatibility limits to ensure the longevity and accuracy of the sensor.

SHORT-TERM EXPOSURE

- Water (distilled, deionized)

- Dilute acids (e.g., hydrochloric acid, sulfuric acid, nitric acid at concentrations ≤10%)

- Dilute bases (e.g., sodium hydroxide, ammonium hydroxide at concentrations ≤10%)

- Alcohols (e.g., isopropyl alcohol, ethanol)

- Hydrogen peroxide (≤3%)

- Aliphatic hydrocarbons (e.g., n-octane)

- Aromatic hydrocarbons (e.g., toluene, chlorobenzene)

- Ketones (e.g., acetone)

USE WITH CAUTION

- Concentrated acids and bases: May cause swelling or degradation over extended exposure.

- Strong oxidizers: Can affect the integrity of the coating.

- High-temperature solvents: Elevated temperatures can increase the permeability of the coating.

NOT RECOMMENDED

- Prolonged exposure to aggressive solvents: Such as benzoyl benzoate or x-chloronaphthalene, especially at temperatures above 150 ºC.

- Mechanical cleaning agents: Abrasive materials can damage the coating.

Best practices when using liquids:

⚬ Rinse after use: Always rinse the sensor with distilled water after exposure to chemicals to prevent residue buildup.

⚬ Avoid prolonged immersion: Limit the duration of exposure to compatible liquids to prevent potential degradation.

Specifications

- Range: 0 to 690 kPa

- Maximum pressure can withstand: 900 kPa

- Accuracy

⚬ factory calibration: ±2 kPa

⚬ custom calibration: ±1 kPa (1 point calibration at atmosphere) - Temperature range: –40 ºC to 125 ºC

- Compatibility

⚬ Gas Compatible (GDX-WRP): Dry gases only

⚬ Liquid & Gas Compatible (GDX-WRPL): Dry gases and Parylene C liquid compatibility - Internal volume of sensor

⚬ with 1/8” NPT Thread Insert attached: 0.786 mL

⚬ with 1/8” Hose Barb Insert attached: 0.623 mL - Connections

⚬ Wireless: Bluetooth® v4.2 (wireless range 30 m unobstructed)

⚬ Wired: USB 2.0 full speed - Battery: 300 mA Li-Poly

⚬ Battery Life (single, full charge): ~24 hours continuous data collection

⚬ Battery Life (lifetime): 2 – 5 years (typical)

Calibration

Go Direct Wide-Range Pressure is calibrated to true atmospheric pressure before shipping. If you wish to re-calibrate to sea level pressure based on your elevation, perform a one-point calibration using a known value as described below. For more information, see How do I calibrate my sensor?

- Connect the sensor to an interface and launch the software.

- Initiate the calibration procedure.

- Enter the known calibration value in the box.

- Once the relative stability reading in the input field stops changing significantly, click or tap Keep to record the input value.

- Click or tap Apply to complete the calibration process. This calibration is automatically stored to the sensor. To restore the default calibration, click Reset to Defaults.

Battery Troubleshooting

- If the sensor won’t turn when on its own, but does when connected to a USB power source, try charging the sensor for at least 2 hours using a known-to-work USB cable.

- If you continue to have trouble, try swapping the battery with a working sensor to see if the problem follows the battery or stays with the sensor.

⚬ If the problem stays with the sensor, the battery is probably not the issue.

⚬ If the problem follows the battery, the battery has likely reached its end of life. - If the battery is indeed at the end of its life, the battery should be replaced.

Go Direct® 300 mAh Replacement Battery (GDX-BAT-300 ) - See How do I remove or replace a Go Direct battery? for more information (including a video).

Rechargeable batteries are covered by a one-year warranty.

Batteries should last two to five years in typical use.

Related Products

- Micro USB to USB-C Cable (

CB-USB-C-MICRO ) - Go Direct® Sensor Cart Charge Station (

GDX-CART-CRG ) - Go Direct® Gas Pressure Sensor (

GDX-GP ) - Pressure Sensor 400 (

PS400-BTA )

Replacement Parts

- Go Direct® 300 mAh Replacement Battery (

GDX-BAT-300 ) - Micro USB Cable (

CB-USB-MICRO )